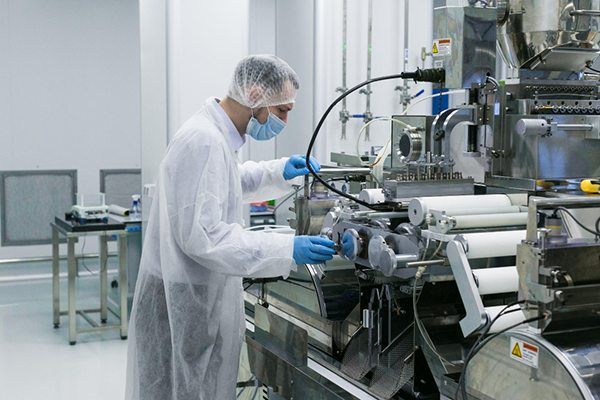

In the first stage of the IML container production process, customers interact with the specialized team at Zhilafe Plast to specify their needs. This stage includes consultation sessions and the receipt of the contract, in which the order details are reviewed and finalized. Following this, our design team starts designing the containers using IML technology. These designs are created precisely according to the customer’s needs and specific requirements. The IML container design not only complies with quality standards but also allows for the use of special graphic designs and in-mold labeling.